Milk, five production sites and many customers

The supply chain of a company comprises partners, activities and processes, which are all involved in added value activities and the delivery of products. Here, the Uelzena supply chain - from the origin of the raw materials to processing and dispatch/sales is explained and the essentials are summarized in a diagram.

SOURCING OF MILK AND AGRICULTURAL RAW MATERIALS

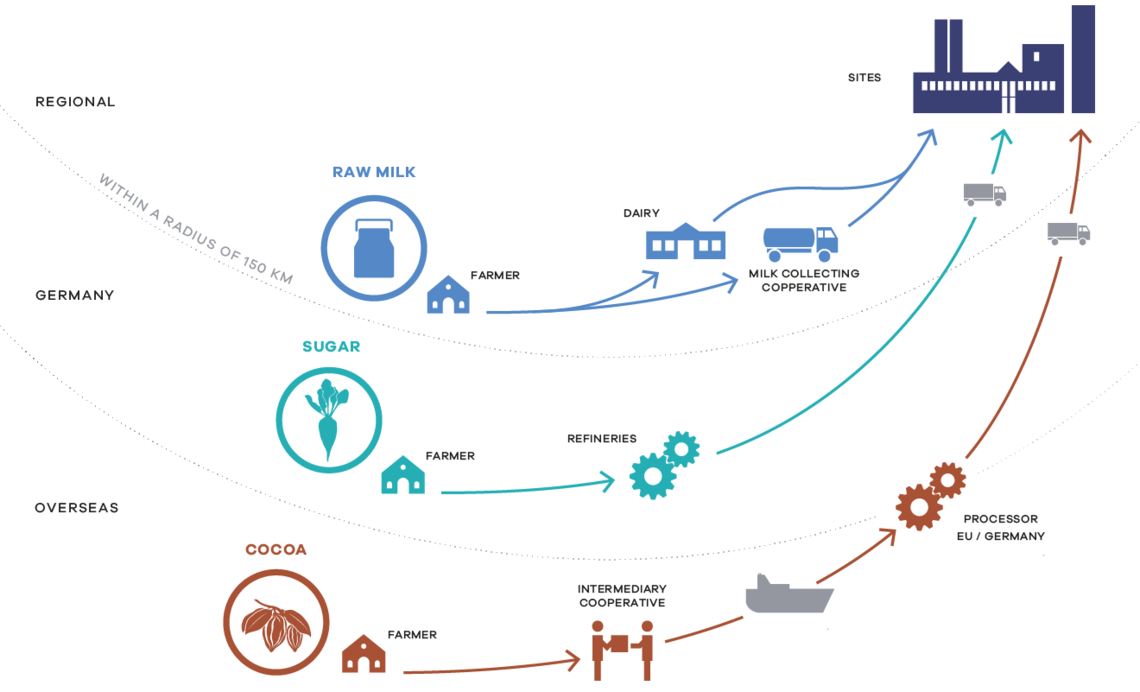

Dairy raw materials such as raw milk or cream are by volume our most important agricultural raw materials. Within our supply chain, we source these dairy raw materials from our member companies and contract suppliers to the Uelzena Group. The raw milk is produced in agricultural businesses; most of them are located within a 150 kilometer radius around our sites.

The conventional sugar for our products is not sourced from overseas. We use only beet sugar from domestic sugar refineries. Even the sugar beets are not imported but grown by farmers from the region. Alternatively, we source our tropical raw materials such as cocoa from refinement plants located in Europe. These companies sometimes buy the cocoa beans from distributors who organize the import. However, they also buy directly from growing countries, predominantly in West Africa, from so called cooperatives. Apart from cocoa, we also source coffee, tea and spices from overseas.

We use agricultural raw materials and semi-finished goods to produce milk powder, butter and butterfats or we refine them in a multi-stage process into finished goods such as instant beverages.

PROCESSING IN THE UELZENA FACTORIES

The Uelzena Group owns four factory sites in their entirety, while one plant is a co-owned as a joint venture with other dairies. All sites are located in the north of Germany in the Federal States of Lower Saxony, Schleswig-Holstein and Saxony-Anhalt. The linear distance between each of them is less than 200 km.

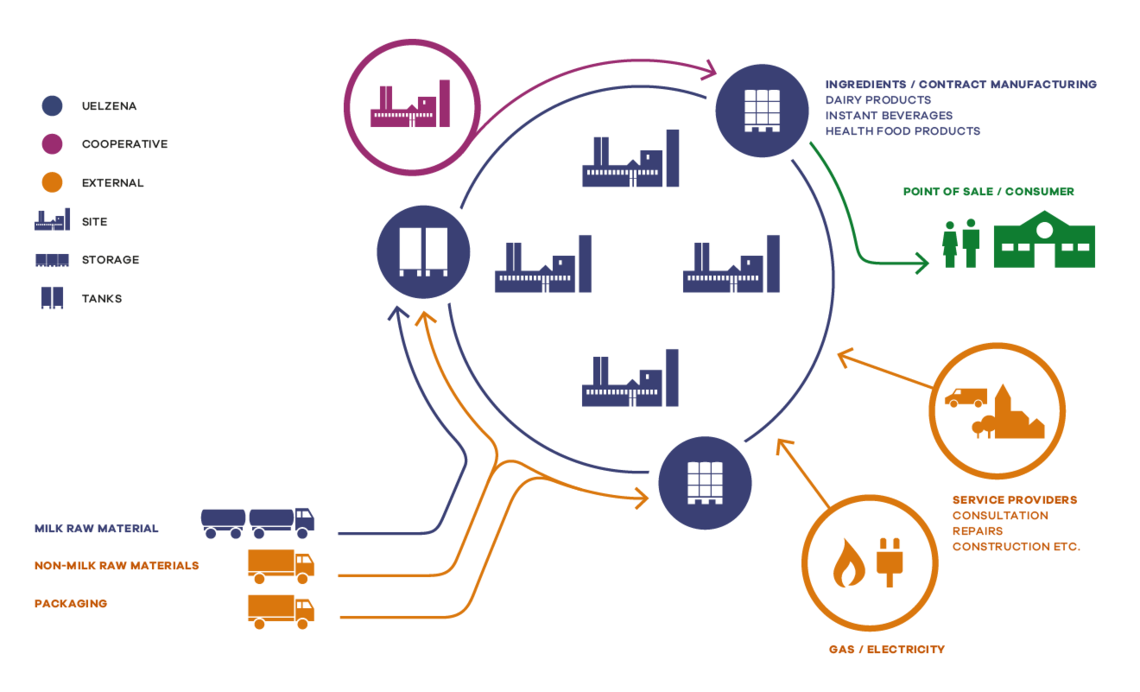

All five sites are exclusively dedicated to processing of the milk raw materials that we receive into dairy ingredients (Uelzena Ingredients) and milk products (Hoche Butter); these products are predominantly intended for commercial and industrial use. Parts of the milk raw materials are, in combination with other additionally purchased raw materials, processed into instant beverages for our Instant Beverage division (Schoppe Instant Beverage, Scho). Health Products (biohealth) and contract manufacturing of our customers’ raw materials round off the production portfolio at the Uelzen site.

At the sites in Uelzen (Uelzena eG) and Bismark (Altmark cheese making), we use gas to generate the energy required for production (electricity, heat, steam) in our own highly efficient combined heat and power plants. For all of the other sites, we purchase the electricity that we need. We also procure non-dairy ingredients, packaging materials and supplementary services from external suppliers.

FINISHED PRODUCTS AND THEIR JOURNEY TO THE CUSTOMER

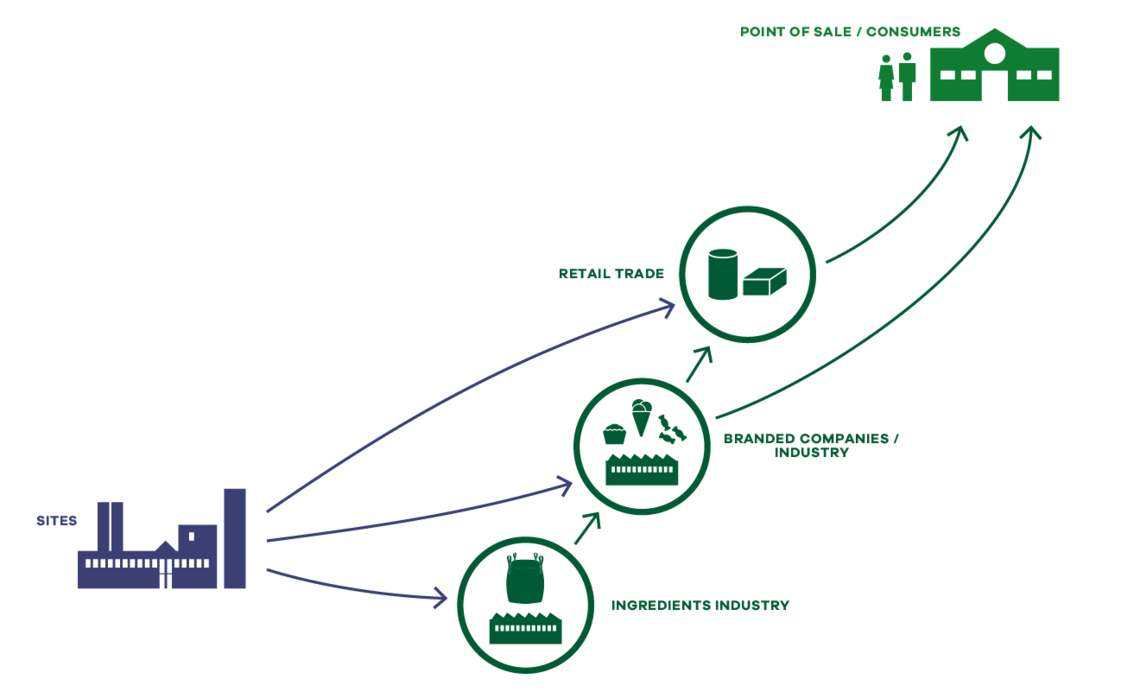

Milk products such as milk powder, butter, butterfat and sweetened condensed milk are sold to the food processing industry under the Uelzena Ingredients brand. In addition, customers also include globally active commodity traders, who in turn resell to industrial companies and manufacturers.

Instant beverages are predominantly private label products such as chocolate drinks, toppings and coffee creamers. The main customer group comprises coffee roasters who - apart from coffee - need a supplementary range for their brand. We also sell our products to so-called vending partners, which are operators of hot beverage vending machines with integrated payment systems. The food service trade also orders instant beverages from us. We supply products from Uelzena’s hot beverage brand Scho to both customer groups.

Uelzena eG has formed a joint venture together with BHI Biohealth International. The buyers are industrial customers who require a supplementary range, or branded companies who have completely outsourced their production. Other distributors such as specialized Internet shops, drugstore chains and the pharmacy wholesale trade are among the biohealth customers as well.

Butter or butterfat branded as Hoche Butter or Trilactis are sold to bakeries via specialized traders. Hoche Butter and the Butaris brand are also sold to German food retailers.

In contract manufacturing processes for the European ingredients industry, liquid raw materials are converted into powdery raw materials by spray drying. Milk products such as butter are also produced in Uelzena plants from liquid milk raw materials sourced from raw material traders.